Read Line and Put Into Multiple String C++

A coil of right-handed laid three-strand rope

A rope is a group of yarns, plies, fibers, or strands that are twisted or braided together into a larger and stronger form. Ropes have tensile force and and so tin can be used for dragging and lifting. Rope is thicker and stronger than similarly constructed cord, string, and twine.

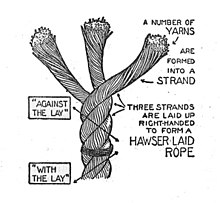

Hawser-laid rope (Seaman'southward Pocket-Volume, 1943)

Construction

Three-strand natural fiber laid line

Rope may exist constructed of any long, stringy, fibrous material, but generally is synthetic of certain natural or synthetic fibres.[ane] [2] [iii] Synthetic fibre ropes are significantly stronger than their natural fibre counterparts, they have a higher tensile strength, they are more resistant to rotting than ropes created from natural fibers, and they tin can be made to float on h2o.[4] But synthetic rope also possess certain disadvantages, including slipperiness, and some tin be damaged more easily past UV light.[5]

Common natural fibres for rope are Manila hemp, hemp, linen, cotton wool, coir, jute, straw, and sisal. Synthetic fibres in use for rope-making include polypropylene, nylon, polyesters (due east.g. PET, LCP, Vectran), polyethylene (e.m. Dyneema and Spectra), Aramids (due east.g. Twaron, Technora and Kevlar) and acrylics (e.chiliad. Dralon). Some ropes are constructed of mixtures of several fibres or use co-polymer fibres. Wire rope is made of steel or other metal alloys. Ropes accept been constructed of other gristly materials such every bit silk, wool, and hair, merely such ropes are not generally available. Rayon is a regenerated fibre used to brand decorative rope.

The twist of the strands in a twisted or braided rope serves non just to go along a rope together, but enables the rope to more evenly distribute tension among the individual strands. Without any twist in the rope, the shortest strand(s) would always be supporting a much college proportion of the total load.

Size measurement

Considering rope has a long history, many systems have been used to specify the size of a rope. In systems that utilise the inch (Majestic and US customary measurement systems), large ropes over 1 inch (25.iv mm) bore – such every bit those used on ships – are measured past their circumference in inches; smaller ropes have a nominal diameter based on the circumference divided past three (as a rough approximation of pi). In the metric system of measurement, the nominal diameter is given in millimetres. The electric current preferred international standard for rope sizes is to give the mass per unit length, in kilograms per metre. Nonetheless, even sources otherwise using metric units may withal give a "rope number" for big ropes, which is the circumference in inches.[vi]

Utilize

Rope has been used since prehistoric times.[7] Information technology is of paramount importance in fields as diverse as construction, seafaring, exploration, sports, theatre, and communications. Many types of knots take been developed to spike with rope, join ropes, and employ rope to generate mechanical advantage. Pulleys can redirect the pulling force of a rope in another direction, multiply its lifting or pulling power, and distribute a load over multiple parts of the same rope to increase safety and subtract wear.

Winches and capstans are machines designed to pull ropes.

Rock climbing ropes

Dynamic kernmantle rock climbing rope with its braided sheath cut to expose the twisted core yarns and core yarn plies

Department through kernmantle rope

The sport of rock climbing uses what is termed "dynamic" rope, an elastic rope which stretches under load to absorb the free energy generated in arresting a fall without creating forces high enough to injure the climber. Such ropes are of kernmantle structure, as described below.

Conversely, "static" ropes have minimal stretch and are non designed to arrest gratuitous falls. They are used in caving, rappelling, rescue applications, and industries such as window washing.

The UIAA, in concert with the CEN, sets climbing-rope standards and oversees testing. Whatsoever rope bearing a GUIANA or CE certification tag is suitable for climbing. Climbing ropes cut easily when nether load. Keeping them away from sharp rock edges is imperative. Previous falls arrested by a rope, damage to its sheath, and contamination past dirt or solvents all weaken a rope and tin render it unsuitable for further sport use.

Stone climbing ropes are designated equally suitable for single, double or twin use. A single rope is the almost mutual, and is intended to be used by itself. These range in thickness from roughly 9 to 11 mm (0.35 to 0.43 in). Smaller bore ropes are lighter, merely wear out faster.

Double ropes are thinner than single, usually 9 mm (0.35 in) and under, and are intended for utilize in pairs. These offer a greater margin of safety against cutting, since information technology is unlikely that both ropes will exist cut, but complicate both belaying and leading. Double ropes may be clipped into alternating pieces of protection, allowing each to stay straighter and reduce both individual and total rope drag.

Twin ropes are thin ropes which must be clipped into the aforementioned piece of protection, in consequence being treated as a unmarried strand. This adds security in situations where a rope may get cutting. Notwithstanding new lighter-weight ropes with greater safe have virtually replaced this type of rope.[ citation needed ]

The butterfly and alpine coils are methods of coiling a rope for carrying.

History

The utilize of ropes for hunting, pulling, fastening, attaching, conveying, lifting, and climbing dates back to prehistoric times. It is likely that the earliest "ropes" were naturally occurring lengths of plant fibre, such as vines, followed soon by the first attempts at twisting and braiding these strands together to form the starting time proper ropes in the modernistic sense of the word. The earliest prove of true rope making is a very small fragment of three-ply cord from a Neanderthal site dated l,000 years ago.[8]

A 40,000-year-one-time tool found in Hohle Fels cave in south-western Germany, originally suggested to be a musical instrument or a religious object, was identified in 2020 as very likely to exist a tool for making rope. It is a 20 cm (8 in) strip of mammoth ivory with 4 holes drilled through it. Each hole is lined with precisely cut spiral incisions. Plant fibres would have been fed through the holes and the tool twisted, creating strong ropes and twines. The spiral incisions would have tended to keep the fibres in identify.[9] After this object was identified as a likely rope-making tool, other 15,000-year-old objects with holes with spiral incisions, fabricated from reindeer antler, establish previously in Cheddar Gorge, Somerset, England announced to have been used to manipulate ropes, for purposes however unclear, just now thought to be for making or manipulating ropes. They were originally named "batons", and thought possibly to accept been carried equally badges of rank.[ix]

Impressions of cordage plant on fired clay provide prove of cord and rope-making engineering science in Europe dating back 28,000 years.[10] Fossilized fragments of "probably ii-ply laid rope of well-nigh 7 mm [0.28 in] diameter" were plant in one of the caves at Lascaux, dating to approximately 15,000 BC.[xi]

The ancient Egyptians were probably the beginning civilization to develop special tools to make rope. Egyptian rope dates back to 4000 to 3500 BC and was generally fabricated of water reed fibres.[12] Other rope in antiquity was made from the fibres of engagement palms, flax, grass, papyrus, leather, or fauna pilus. The apply of such ropes pulled by thousands of workers allowed the Egyptians to move the heavy stones required to build their monuments. Starting from approximately 2800 BC, rope made of hemp fibres was in utilise in China. Rope and the craft of rope making spread throughout Asia, Bharat, and Europe over the next several thousand years.

From the Center Ages until the 18th century, in Europe ropes were synthetic in ropewalks, very long buildings where strands the full length of the rope were spread out and then laid up or twisted together to form the rope. The cable length was thus fix by the length of the available rope walk. This is related to the unit of length termed cablevision length. This allowed for long ropes of up to 300 yards (270 chiliad) long or longer to be made. These long ropes were necessary in shipping as short ropes would require splicing to brand them long plenty to use for sheets and halyards. The strongest form of splicing is the short splice, which doubles the cross-exclusive area of the rope at the area of the splice, which would cause problems in running the line through pulleys. Whatsoever splices narrow plenty to maintain polish running would be less able to support the required weight.[ citation needed ]

Leonardo da Vinci drew sketches of a concept for a ropemaking auto, simply information technology was never built. Remarkable feats of construction were accomplished using rope simply without advanced technology: In 1586, Domenico Fontana erected the 327 ton obelisk on Rome's Saint Peter's Square with a concerted endeavor of 900 men, 75 horses, and countless pulleys and meters of rope. By the tardily 18th century several working machines had been built and patented.

Some rope is still made from natural fibres, such every bit coir and sisal, despite the dominance of synthetic fibres such equally nylon and polypropylene, which accept go increasingly popular since the 1950s.

-

A ropemaker at work, c. 1425

-

A German ropemaker, c. 1470

-

Public demonstration of historical ropemaking technique

Styles of rope construction

Laid or twisted rope

Illustration of the Due south and Z naming convention

Laid rope, also called twisted rope, is historically the prevalent form of rope, at least in mod Western history. Mutual twisted rope generally consists of three strands and is normally correct-laid, or given a concluding right-handed twist. The ISO 2 standard uses the capital letter letters S and Z to indicate the two possible directions of twist, equally suggested by the direction of slant of the key portions of these ii letters. The handedness of the twist is the direction of the twists as they progress away from an observer. Thus Z-twist rope is said to be correct-handed, and Due south-twist to be left-handed.

Twisted ropes are built up in iii steps. First, fibres are gathered and spun into yarns. A number of these yarns are then formed into strands by twisting. The strands are then twisted together to lay the rope. The twist of the yarn is opposite to that of the strand, and that in turn is contrary to that of the rope. It is this counter-twist, introduced with each successive performance, which holds the final rope together as a stable, unified object.[thirteen]

Rope making using the twisted rope method on a 1928 Metters Rope Making Machine

Traditionally, a three strand laid rope is chosen a plain- or hawser-laid, a iv strand rope is called shroud-laid, and a larger rope formed by counter-twisting three or more than multi-strand ropes together is called cablevision-laid.[14] Cable-laid rope is sometimes clamped to maintain a tight counter-twist rendering the resulting cable about waterproof. Without this feature, deep water sailing (earlier the advent of steel chains and other lines) was largely impossible, as whatsoever appreciable length of rope for anchoring or send to ship transfers, would go too waterlogged – and therefore too heavy – to lift, fifty-fifty with the aid of a capstan or windlass.

I property of laid rope is partial untwisting when used.[15] This can cause spinning of suspended loads, or stretching, kinking, or hockling of the rope itself. An additional drawback of twisted construction is that every fibre is exposed to abrasion numerous times along the length of the rope. This ways that the rope can degrade to numerous inch-long fibre fragments, which is not easily detected visually.[ commendation needed ]

Twisted ropes have a preferred management for coiling. Normal right-laid rope should exist coiled clockwise, to prevent kinking. Coiling this mode imparts a twist to the rope. Rope of this type must exist bound at its ends by some means to prevent untwisting.

Braided rope

A rope braiding automobile at the Arbetets Museum (Museum of Work) in Norrköping, Sweden

While rope may be made from three or more than strands,[xvi] modern braided rope consists of a braided (tubular) jacket over strands of fiber (these may besides be braided). Some forms of braided rope with untwisted cores have a particular advantage; they do non impart an boosted twisting force when they are stressed. The lack of added twisting forces is an reward when a load is freely suspended, as when a rope is used for rappelling or to suspend an arborist. Other specialized cores reduce the shock from arresting a fall when used every bit a role of a personal or group safety system.

Braided ropes are generally made from nylon, polyester, polypropylene or high performance fibers such as high modulus polyethylene (HMPE) and aramid. Nylon is called for its strength and rubberband stretch properties. Withal, nylon absorbs h2o and is 10–15% weaker when moisture. Polyester is virtually 90% as potent as nylon but stretches less nether load and is non affected by h2o. It has somewhat better UV resistance, and is more abrasion resistant. Polypropylene is preferred for low cost and light weight (it floats on water) but information technology has limited resistance to ultraviolet lite, is susceptible to friction and has a poor heat resistance.[ citation needed ]

Braided ropes (and objects like garden hoses, fibre optic or coaxial cables, etc.) that have no lay (or inherent twist) uncoil ameliorate if each alternate loop is twisted in the opposite direction, such as in figure-viii coils, where the twist reverses regularly and essentially cancels out.

Single braid consists of an even number of strands, eight or twelve being typical, braided into a circular pattern with half of the strands going clockwise and the other one-half going anticlockwise. The strands can interlock with either twill or manifestly weave. The central void may be large or modest; in the former example the term hollow complect is sometimes preferred.

Double braid, also called complect on complect, consists of an inner braid filling the central void in an outer braid, that may exist of the same or unlike cloth. Frequently the inner complect fibre is chosen for forcefulness while the outer braid fibre is chosen for abrasion resistance.

In solid braid, the strands all travel the same direction, clockwise or anticlockwise, and alternate between forming the outside of the rope and the interior of the rope. This structure is popular for general purpose utility rope merely rare in specialized high performance line.

Kernmantle rope has a core (kern) of long twisted fibres in the center, with a braided outer sheath or mantle of woven fibres. The kern provides about of the force (about lxx%), while the mantle protects the kern and determines the handling properties of the rope (how easy it is to concur, to tie knots in, and then on). In dynamic climbing line, core fibres are normally twisted to make the rope more than elastic. Static kernmantle ropes are made with untwisted cadre fibres and tighter complect, which causes them to exist stiffer in improver to limiting the stretch.

Other types

Plaited rope is made by braiding twisted strands, and is also called foursquare braid.[17] Information technology is not as circular as twisted rope and coarser to the touch. It is less prone to kinking than twisted rope and, depending on the textile, very flexible and therefore piece of cake to handle and knot. This construction exposes all fibres as well, with the same drawbacks as described above. Brait rope is a combination of braided and plaited, a non-rotating alternative to laid three-strand ropes. Due to its excellent energy-absorption characteristics, information technology is often used past arborists. It is also a popular rope for anchoring and can be used every bit mooring warps. This type of construction was pioneered by Yale Cordage.

Endless winding rope is made by winding single strands of high-performance yarns around 2 end terminations until the desired break forcefulness or stiffness has been reached. This type of rope (often specified equally cable to make the difference betwixt a braided or twined structure) has the reward of having no construction stretch as is the instance with higher up constructions. Countless winding is pioneered by SmartRigging and FibreMax.

Gallery of µCT/micro-CT images and animations

2D images / sections

2nd flying-throughs/sections

3D renderings

3D flight-throughs/sections

Treatment

Cordage aboard the French training transport Mutin

Rope made from hemp, cotton or nylon is generally stored in a cool dry place for proper storage. To forbid kinking information technology is commonly coiled. To prevent fraying or unravelling, the ends of a rope are bound with twine (whipping), tape, or estrus shrink tubing. The ends of plastic fibre ropes are frequently melted and fused solid; nonetheless, the rope and knotting expert Geoffrey Budworth warns against this practice thus:[18]

Sealing rope ends this way is lazy and dangerous. A tugboat operator once sliced the palm of his hand open down to the sinews after the hardened (and obviously sharp) cease of a rope that had been heat-sealed pulled through his grasp. There is no substitute for a properly made whipping.

If a load-begetting rope gets a precipitous or sudden jolt or the rope shows signs of deteriorating, it is recommended that the rope be replaced immediately and should be discarded or only used for non-load-begetting tasks.[19] [20]

The average rope life-span is five years. Serious inspection should be given to line after that bespeak.[ citation needed ] However, the use to which a rope is put affects frequency of inspection. Rope used in mission-disquisitional applications, such as mooring lines or running rigging, should be regularly inspected on a much shorter timescale than this, and rope used in life-critical applications such as mountain climbing should be inspected on a far more than frequent basis, up to and including before each use.

Avoid stepping on climbing rope, as this might force tiny pieces of stone through the sheath, which can somewhen deteriorate the core of the rope.

Ropes may exist flemished into coils on deck for safety, presentation, and tidiness.

Many types of filaments in ropes are weakened by corrosive liquids, solvents, and high temperatures. Such damage is specially treacherous because information technology often invisible to the heart.[21]

Daze loading should be avoided with full general apply ropes, equally it can damage them.[22] All ropes should be used within a rubber working load, which is much less than their breaking force.

A rope under tension – especially if it has a smashing deal of elasticity – can exist dangerous if parted. Care should be taken effectually lines under load.

Terminology

"Rope" is a material, and a tool. When it is assigned a specific function it is oft referred to as a "line", especially in nautical usage. A line may get a farther distinction, for example sail command lines are known as "sheets" (e.g. A jib sheet).

A halyard is a line used to raise and lower a sail, typically with a shackle on its canvas finish. Other maritime examples of "lines" include anchor line, mooring line, line-fishing line, marline. Common items include clothesline and a chalk line.

In some marine uses the term rope is retained, such as man rope, bolt rope, and bell rope.

See also

- Cordage Found

- Fid – Ropework tool (splicing tool)

- Flagellation, besides known equally Flogging – Whipping as a penalty

- Hanging – Death past interruption of a person by a noose or ligature around the neck

- Hawser – Nautical mooring line

- International Year of Natural Fibres – United Nations observance of 2009

- Knot – Method of fastening or securing linear material

- Mooring line materials

- Physical restraint

- Rigging – Ropes, cables and bondage which back up masts of sailing ships

- Rope bondage – Chains involving the use of rope to restrict motion, wrap, suspend, or restrain a person

- Rope lock (in theatre wing organization)

- Rope splicing – Semi-permanent articulation between two ropes

- Ropework

- Sheet (sailing) – One of the lines on a sail ship

- Simple suspension bridge – Type of bridge

- Single-rope technique

- Skipping rope, also known every bit Jump rope – Game in which one or more than participants jump over a swung rope

- Tightrope walking – Skill of walking along a taut wire or rope

- Whipping knot – Bounden around the end of a rope to preclude information technology from fraying

References

- ^ Jr, John V. Noel (1988-12-fifteen). Knight'southward Modern Seamanship. John Wiley & Sons. ISBN9780471289487.

- ^ Army Field Manual FM five-125 (Rigging Techniques, Procedures and Applications) (PDF). Technical Transmission No. 3-34.86/Marine Corps, Reference Publication iii-17.7J. The The states Regular army. 2012.

- ^ Carver, R.K. (2009). Stagecraft Fundamentals: A Guide and Reference for Theatrical Product. Focal Press. p. 250. ISBN978-0-240-80857-4 . Retrieved 15 November 2018.

- ^ Coles, A. (2009). Skipper'south Onboard Knot Guide: Knots, Bends, Hitches and Splices. A&C Blackness. p. 3. ISBN978-0-7136-8934-ane . Retrieved 15 November 2018.

- ^ International Clan of Burn down Chiefs; National Fire Protection Clan (2008). Fundamentals of Firefighter Skills. Jones & Bartlett Learning, LLC. p. 499. ISBN978-0-7637-5342-9 . Retrieved 15 November 2018.

- ^ H A McKenna, J. W. S. Hearle, N O'Hear, Handbook of Fibre Rope Engineering, Elsevier, 2004,ISBN 1855739933, folio 18

- ^ ListVerse.com (November 2009). The Ultimate Volume of Tiptop 10 Lists: A Mind-Boggling Collection of Fun, Fascinating and Bizarre Facts on Movies, Music, Sports, Crime, Celebrities, History, Trivia and More. Ulysses Printing. ISBN978-ane-56975-715-four.

- ^ "50,000-year-old string plant at France Neanderthal site". BBC. 13 Apr 2020. Retrieved 20 April 2020.

- ^ a b McKie, Robin (one Baronial 2020). "Accept a tusk, drill holes, weave a rope – and alter the course of history". The Guardian. Article has photo of the Hohle Fels rope-making tool.

- ^ Small, Meredith F. (April 2002), "Cord theory: the tradition of spinning raw fibers dates back 28,000 years. (At The Museum).", Natural History, 111 (3): 14(2)

- ^ J.C. Turner and P. van de Griend (ed.), The History and Science of Knots (Singapore: World Scientific, 1996), 14.

- ^ (Run across http://world wide web.madehow.com/Book-2/Rope.html, word-for-word not sure which "plagiarized" which)

- ^ J. Bohr and K. Olsen (2010). "The ancient fine art of laying rope". EPL. 93 (6): 60004. arXiv:1004.0814. Bibcode:2011EL.....9360004B. doi:10.1209/0295-5075/93/60004. S2CID 20678986.

- ^ K.Southward. Nares (1865), Seamanship (third ed.), London: James Griffin, p. 23

- ^ McFarland, Cynthia (2013-08-06). HORSEMANS GT TACK & EQUIPMENT: F. Rowman & Littlefield. ISBN978-0-7627-9598-7.

- ^ Kyosev, Y (2015). Braiding applied science for textiles. Cambridge, U.k. Waltham, MA, United states of america: Elsevier/ Woodhead Pub. ISBN978-0-85709-135-two.

- ^ Boating. June 1965.

- ^ Budworth, Geoffrey (1985). The Knot Book . New York: Sterling Publishing Co., Inc. p. 37. ISBN0-8069-7944-5.

- ^ "Air Winch Prophylactic Info". AirWinchSafety.com . Retrieved x Oct 2012.

- ^ "Wire Rope Inspections". U.Due south. DOL, OSHA. Retrieved x October 2012.

- ^ National Research Quango (U.S.) (1975). Mechanical Rope and Cablevision: Report of the Ad Hoc Committee on Mechanical Rope and Cablevision, National Materials Advisory Board, Committee on Sociotechnical Systems, National Inquiry Quango. National Academies. pp. 51–54.

- ^ American Telephone and Telegraph Visitor (1931). Use, Care, and Maintenance of Manila Rope and Blocks.

Sources

- Gaitzsch, Westward. Antike Korb- und Seilerwaren, Schriften des Limesmuseums Aalen Nr. 38, 1986

- Gubser, T. Die bäuerliche Seilerei, Thou. Krebs AG, Basel, 1965

- Hearle, John W. S. & O'Hear & McKenna, North. H. A. Handbook of Fibre Rope Technology, CRC Press, 2004

- Lane, Frederic Chapin, 1932. The Rope Factory and Hemp Merchandise of Venice in the Fifteenth and Sixteenth Centuries, Journal of Economical and Business History, Vol. 4 No. 4 Suppl. (Baronial 1932).

- Militzer-Schwenger, L.: Handwerkliche Seilherstellung, Landschaftsverband Westfalen-Lippe, 1992

- Nilson, A. Studier i svenskt repslageri, Stockholm, 1961

- Pierer, H.A. Universal-Lexikon, Altenburg, 1845

- Plymouth Cordage Company, 1931. The Story of Rope; The History and the Modernistic Development of Rope-Making, Plymouth Cordage Visitor, N Plymouth, Massachusetts

- Sanctuary, Anthony, 1996. Rope, Twine and Net Making, Shire Publications Ltd., Cromwell Business firm, Princes Risborough, Buckinghamshire.

- Schubert, Pit. Sicherheit und Risiko in Fels und Eis, Munich, 1998

- Smith, Bruce & Padgett, Allen, 1996. On Rope. N American Vertical Rope Techniques, National Speleological Society, Huntsville, Alabama.

- Strunk, P.; Abels, J. Das große Abenteuer 2.Teil, Verlag Karl Wenzel, Marburg, 1986.

- Teeter, Emily, 1987. Techniques and Terminology of Rope-Making in Ancient Arab republic of egypt, Periodical of Egyptian Archaeology, Vol. 73 (1987).

- Tyson, William, no date. Rope, a History of the Difficult Fibre Cordage Industry in the United Kingdom, Wheatland Journals, Ltd., London.

Further reading

- Bodmer, Rudolph John; Bodmer, Amelie Willard (1914). "Rope". The Book of Wonders: Gives Evidently and Elementary Answers to the Thousands of Everyday Questions that are Asked and which All Should be Able To, Only Cannot Answer. Presbrey syndicate. pp. 353 onwards.

- Herkommer, Mark (1995). FM five-125: Rigging Techniques, Procedures, and Applications. Washington, DC: United States Department of the Army.

External links

| | Wikimedia Commons has media related to Rope. |

| | Look up rope in Wiktionary, the free dictionary. |

- Ropewalk: A Cordage Engineer'southward Journey Through History History of ropemaking resource and nonprofit documentary film

- Watch How Do They Braid Rope?

Source: https://en.wikipedia.org/wiki/Rope

0 Response to "Read Line and Put Into Multiple String C++"

Post a Comment